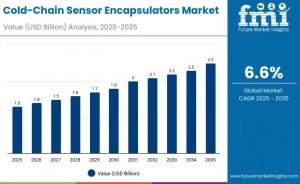

Cold-Chain Sensor Encapsulators Market in APAC and USA to Double from USD 1.3 Billion in 2025 to USD 2.5 Billion by 2035

Japan’s cold-chain sensor encapsulators market, value at USD 200.0 Mn in 2025, is dominat by temperature sensors due to their role in food logistics monitoring.

NEWARK, DE, UNITED STATES, November 10, 2025 /EINPresswire.com/ -- The cold-chain sensor encapsulators market is on a strong growth trajectory, expanding from USD 1.3 billion in 2025 to USD 2.5 billion by 2035, reflecting a CAGR of 6.6%. The surge is primarily driven by the modernization of pharmaceutical logistics, the rise of biologic and vaccine transport, and growing demand for perishable food monitoring. As the world increasingly relies on temperature-sensitive supply chains, encapsulated sensors are emerging as critical enablers of reliability, accuracy, and regulatory compliance.

Encapsulation technology ensures that sensors—responsible for monitoring temperature, humidity, shock, and location remain shielded from environmental stress, vibration, and moisture. In particular, temperature sensors dominate the market, holding a 38.7% share in 2025, thanks to their proven reliability and precision in maintaining cold-chain integrity across varying environmental conditions.

Unlock Growth Potential – Request Your Sample Now and Explore Market Opportunities!

https://www.futuremarketinsights.com/reports/sample/rep-gb-27063

Market Dynamics and Growth Outlook

Between 2025 and 2030, the industry is projected to generate an additional USD 0.6 billion in market value, largely driven by the digital transformation of healthcare logistics. Between 2030 and 2035, a further USD 0.6 billion will be attributed to the adoption of AI-driven and IoT-based tracking systems, marking a pivotal shift toward intelligent cold-chain ecosystems.

From 2020 to 2024, momentum accelerated as biologic drugs and temperature-sensitive vaccines, such as those for COVID-19 and mRNA-based treatments, emphasized the importance of precision monitoring. Epoxy and silicone encapsulants proved essential in ensuring sensor resilience under fluctuating conditions.

By 2035, the integration of wireless sensing, blockchain-enabled traceability, and energy-efficient encapsulation materials will define the next era of smart logistics systems.

Why the Market Is Growing

The market’s rapid growth is fueled by the need for real-time tracking, improved sensor protection, and compliance with global Good Distribution Practices (GDP). As biologic and pharmaceutical shipments demand stricter temperature assurance, encapsulation technologies enable durability and consistent data transmission across extreme conditions.

Rising consumer demand for safe and traceable food logistics also reinforces the market. Encapsulated sensors are now embedded in packaging, containers, and pallets, offering precise environmental visibility from factory to pharmacy or supermarket.

Segmental Analysis

By Sensor Type:

• Temperature Sensors dominate with a 38.7% share, serving as the backbone of cold-chain reliability.

• The emergence of humidity and shock sensors complements this segment, ensuring holistic environmental data integrity.

By Encapsulation Material:

• Epoxy Resins lead with 40.1% share in 2025, prized for their adhesion, dielectric strength, and resistance to vibration.

• Ongoing R&D in low-viscosity and rapid-curing epoxy systems supports miniaturized, energy-efficient sensor production.

By Application:

• Pharmaceutical Cold-Chain Monitoring accounts for 37.9% of the market, with expanding biologic and vaccine logistics networks serving as primary demand drivers.

• Perishable Food Logistics follows closely, boosted by global demand for temperature-verified food delivery systems.

By End Use:

• Pharmaceuticals and Healthcare dominate with a 43.6% share, as automation and smart systems transform distribution.

• Other sectors, including food & beverages and biotechnology, are fast adopting encapsulated sensor systems for compliance and quality assurance.

Key Trends and Opportunities

• IoT-Enabled Encapsulation: Real-time cloud-based monitoring is merging with predictive analytics to preempt temperature breaches.

• Material Innovation: R&D in self-healing polymers and bio-compatible encapsulants enhances sensor lifespan and sustainability.

• Battery-Less Sensors: Energy-harvesting encapsulated devices are gaining traction for long-term, maintenance-free operation.

• Smart Packaging Integration: Combined use of blockchain and AI analytics offers end-to-end visibility for pharmaceuticals and perishables.

Regional Insights

Asia-Pacific (APAC) remains the fastest-growing region, led by South Korea (7.0% CAGR), Japan (6.9%), China (6.4%), and India (6.3%). Growth is underpinned by expanding pharmaceutical infrastructure, digital logistics integration, and strong governmental support for vaccine cold-chain modernization.

• South Korea is pioneering AI- and 5G-driven logistics, blending semiconductor precision with encapsulation engineering.

• Japan leverages polymer expertise and robotics for ultra-sensitive sensor encapsulation.

• China’s booming biopharma exports and automation investments are expanding smart sensor production.

• India focuses on smart cold-chain networks and biopolymer R&D, ensuring improved accuracy and sustainability.

In North America, the United States maintains a 6.5% CAGR, fueled by the expansion of biopharma logistics and FDA temperature validation standards. Cloud monitoring and automated tracking systems are key accelerators.

In Europe, Germany and the United Kingdom are advancing through high-grade epoxy encapsulants and compliance-centric cold-chain systems. Stringent EU regulations and strong pharmaceutical exports sustain regional momentum.

Get the Complete Market Intelligence Report

Unlock comprehensive data on regional performance, emerging technologies, and growth projections. Download or purchase the full report here:

Buy Full Report – https://www.futuremarketinsights.com/checkout/27063

Competitive Landscape

The market is moderately consolidated, with leading players focusing on accuracy, data integrity, and encapsulant durability.

• Sensitech (Carrier) leads through integrated logistics and real-time analytics, collaborating with Qualcomm Technologies for next-gen visibility tools.

• ELPRO strengthens its position in GMP-compliant monitoring systems for pharmaceuticals.

• Zebra Technologies advances industrial automation through its connected factory portfolio, launched at Automate 2024.

• SpotSee, LogTag Recorders, Tive, and Testo are emphasizing affordable and scalable encapsulation solutions for global cold-chain networks.

Key Developments

• October 2024: Sensitech (Carrier) partners with Qualcomm Technologies to enhance life-science shipment visibility through IoT and analytics integration.

• May 2024: Zebra Technologies introduces a suite of industrial automation solutions combining sensing, machine vision, and robotics under its automation division.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Have a Look at Related Research Reports on the Packaging Domain:

Styrene Compartment Boxes Market - https://www.futuremarketinsights.com/reports/styrene-compartment-boxes-market

Steel Roll-on Tube Market - https://www.futuremarketinsights.com/reports/steel-roll-on-tube-market

Alginate Films Market - https://www.futuremarketinsights.com/reports/alginate-films-market

Backpack Systems Market - https://www.futuremarketinsights.com/reports/backpack-systems-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.